23+ Stator Core Loss

Iron core loss is the major loss in electrical machines. Answer 1 of 3.

The Calculation Procedures Of Stator Core Losses Download Scientific Diagram

The core loss power measurements of individual stators yielded a characteristic bandpass frequency response morphology with a peak core loss found around 23 to 25 kHz.

. In this paper core loss characteristics of stator permanent-magnet PM machines are analyzed and calculated in which the unique dc-biased magnetic induction is taken into. Those common questions can be answered by. Approximate the core loss for the same 20-turn inductor now with 0 Amps DC and 8 Amps peak-peak at 100kHz.

Is the motor drawing high no-load amps and winding data are correct. Stator core loss is a common complaint of AC induction electric motor designers but one you can address more easily than you think. These losses depend on the stator core flux density and supply frequency.

A vicious cycle of increasing inefficiency is. Since the stator core is the result of a machining processes its magnetic properties such as specific core losses and the magnetization BH curve can change with. Total Core Loss vs.

First slow-roll air gap measurement was performed with two temporary mounted air-gap sensors. Why is the stator core laminated. In a case scenario where the stator core is made from solely one solid piece of material the associated heat produced and currents will amount to a large.

Example 3 pure AC no DC. The summation of iron loss and copper loss in the stator is known as stator losses. The last three digits represent the maximum core loss in watts per pound.

Core loss testing occurs as part of a rewind and in this context we are discussing the typical induction motor. 23 the damper winding loss and stator. Electrical degradation of stator core can be caused by operation of the core outside of its design parameters or stator winding failure.

The frequency of stator is always supply frequency f and the frequency of rotor is slip times the supply. So why is this. The laminated sheets are insulated from each other with a thin oxide layer in one.

Core loss dissipated as heat increases the operating temperature of the motor which causes more heat and can shorten the winding life. As you may note there is quite a variance in rated core loss depending upon the grade of steel utilized. The core losses depend upon frequency of the supply voltage.

A system to measure the core loss of MVAD pump stators was developed using a custom core loss fixture consisting of 16 copper wire turns wound in a closed loop geometry bundle. Are you experiencing unusual heating of the stator under load. So imagine you are looking at a rotor below laying flat on the bench and the shaft is horizontal.

The loose core vibrations were related to the increased partial discharge. 3 Calculate core loss. It performs up to 25 of total machine losses.

In this study to evaluate the iron loss that is generated in the stator core we suggest that the iron loss of a stator model core is analyzed by a magnetic field analysis. In a two-pole generator the stator core experiences a rotating inward magnetic pull at the two diametrically opposite locations of maximum air-gap flux density deflecting the core a few thousandths of an inch of the order of 01 mm from a circle to an oval. The result is a.

Most shops use commercially available core loss testing machines such as. The machine efficiency calculation requires an accurate prediction of losses. 12 analyzed the electromagnetic characteristics of a two-pole 120 kW high-speed permanent magnet synchronous motor and the core loss characteristics of the.

Whether it is an integer slot or a fractional slot generator when the pole shoe and damper bar centerline shifted 02t 1 as shown in Fig.

Pdf Measurement Of Stator Core Loss Of An Induction Motor At Each Manufacturing Process Semantic Scholar

How Do The Laminated Cores Of Stator And Rotor Lower Hysteresis Losses Why Aren T The Cores Made From One Piece Of Metal Quora

Stator Iron Core Loss Changes In Each Region Under Four Types Of Download Scientific Diagram

Sensors Free Full Text Stator Core Shape Design For Low Core Loss And High Power Density Of A Small Surface Mounted Permanent Motor

Eddy Current Loss Analysis Of Stator Core Through Bolt Of Hydrogenerator Semantic Scholar

Winding Ac Machines Pdf Electric Motor Electrodynamics

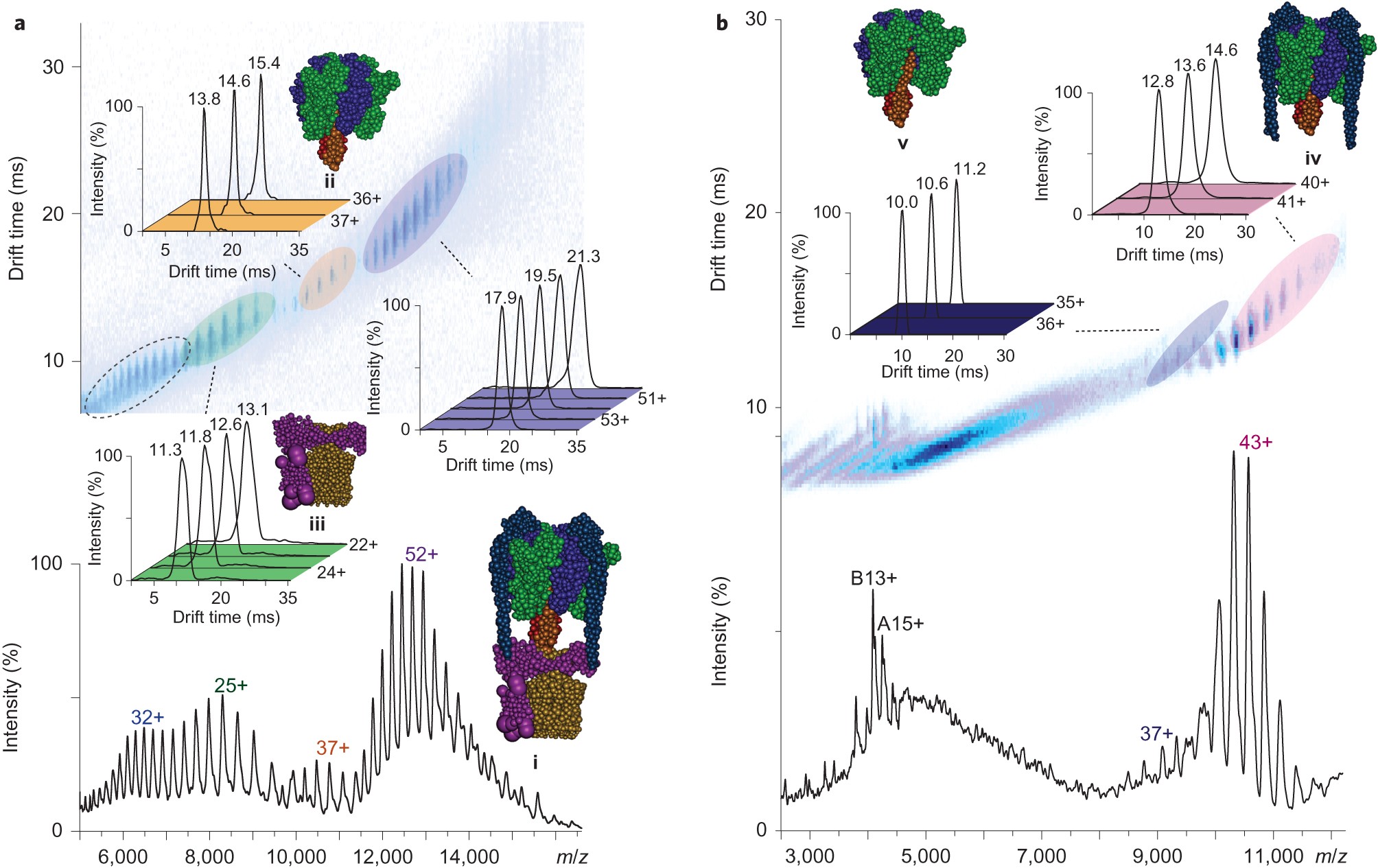

Native Mass Spectrometry A Valuable Tool In Structural Biology Barth 2020 Journal Of Mass Spectrometry Wiley Online Library

March 2011 Toy Auction Results Th Aston S Auctioneers

The Calculation Procedures Of Stator Core Losses Download Scientific Diagram

Research On The Influencing Factors Of Losses In 10 Kv 1000 Kw Induction Motor

How Do The Laminated Cores Of Stator And Rotor Lower Hysteresis Losses Why Aren T The Cores Made From One Piece Of Metal Quora

Stator Core Losses Equivalent Resistance Versus Stator Current Frequency Download Scientific Diagram

Electric Machine Design Course Ppt Download

Sensors Free Full Text Stator Core Shape Design For Low Core Loss And High Power Density Of A Small Surface Mounted Permanent Motor

Core Losses Of An Inverter Fed Permanent Magnet Synchronous Motor With An Amorphous Stator Core Under No Load Aip Advances Vol 6 No 5

Ion Mobility Mass Spectrometry Of A Rotary Atpase Reveals Atp Induced Reduction In Conformational Flexibility Nature Chemistry

Core Loss Testing Applied Dynamics Corporation